Delivery program

| Dimensions | Tooth | |||||

|---|---|---|---|---|---|---|

| mm | inch | 0,75/1,25 | 1/1,3 | 1,4/2 | 2/3 | 3/4 |

| 34 × 1,10 | 1 1/4 × .042 | ■ | ■ | |||

| 41 × 1,30 | 1 1/2 × .050 | ■ | ■ | ■ | ||

| 54 × 1,30 | 2 × .063 | ■ | ■ | ■ | ■ | |

| 54 × 1,60 | 2 × .063 | ■ | ■ | ■ | ■ | |

| 67 × 1,60 | 2 5/8 × .063 | ■ | ■ | ■ | ||

| 80 × 1,60 | 3 × .063 | ■ | ■ | ■ | ||

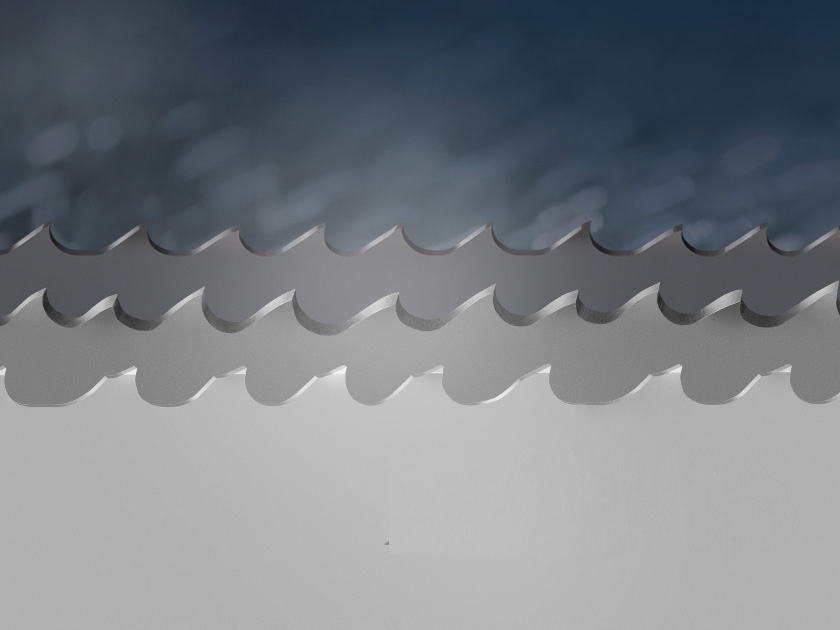

HIGH-PERFORMANCE BAND SAW BLADES

Key features

- Specially Designed Cutting Geometry

- Efficient Chip Removal

- Enhanced Stability

Frequently asked questions

What is a bi-metal Band Saw Blade?

Bi-metal Band Saw Blades combine the high flexibility of the base band, made of specially alloyed heat-treated steel with the enormous resistanceof the tooth tips made of hardened and tempered high-speed steel (HSS) in the qualities M42 and M51.

What does tooth pitch mean?

The tooth pitch refers to the distance between the individual tooth tips on the saw blade and is measured in teeth per inch (ZpZ). A larger tooth pitch means a greater distance between the tooth tips, while a smaller tooth pitch means a narrower distance between the tooth tips. For optimum sawing results, the correct tooth pitch should be always ensured.

What does M42 and M51 mean?

M42 and M51 are material descriptions of the American AISI standard. Both are high-speed steels, whereby M51 is a powder metallurgically produced material.

What is the difference between constant and variable tooth pitch?

With constant tooth pitch, all tooth tips have a constant distance to each other. With variable tooth pitch, the distances vary within a toothing interval.